ERP Replacements Are Dead. The Agentic AI Overlay Is Here

Welcome to DX Brief - Manufacturing, where every week we interview practitioners and distill industry podcasts and conferences into what you need to know.

In today's issue:

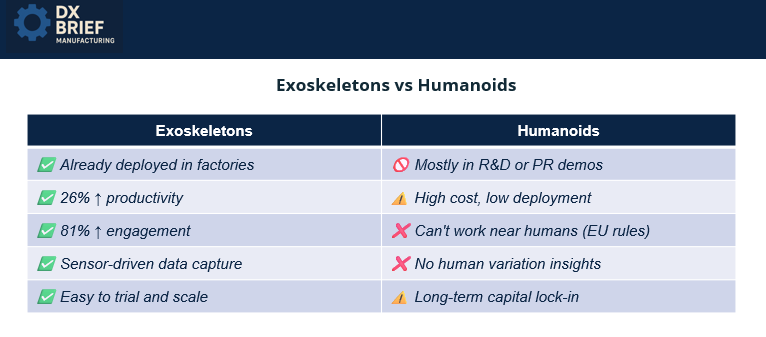

The exoskeleton vs humanoid ROI in real factories: augmenting humans beats replacing them

QAD’s agentic AI plus composable ERP beats the traditional 12-24 month ERP disruption model

How Nissan is breaking down silos in automotive R&D with virtual data centralization and lineage tracking

1. The exoskeleton vs humanoid ROI in real factories: augmenting humans beats replacing them

DBR77 Conference Industrial R(E)volution, Panel: Humanoids or Exoskeletons: Solutions Transforming Human-Machine Relations in Industry with Steffen Ganders (German Bionic), Jan Kuschan (Fraunhofer IPK), Daniel Kottlarz (QUADRUPED Robotics), and Lennart Vulprecht (Generation Robots) (Nov. 12, 2025)

While humanoid robots capture headlines with $20 billion in investment, exoskeletons are quietly winning in actual factories. German Bionic’s active exoskeletons (powered by AI and battery-driven motors providing up to 36kg of lift support) are deployed across industries achieving 26% productivity increases, 81% higher employee engagement, and 35% lower worker attrition.

TLDR:

By augmenting human capabilities rather than replacing workers, active exoskeletons address acute labor shortages (US has 500,000 open manufacturing jobs now, projected to reach 2 million by 2030).

Exoskeletons as "technical assistive systems" (not personal protective equipment) require simpler deployment, function like adjustable-height desks, and keep human flexibility / intuition / creativity while reducing physical strain.

Meanwhile, humanoids face strict regulatory hurdles: under current EU machine directives, they must be separated from human workers, limiting them to repetitive tasks in controlled environments.

The hidden costs of labor scarcity dwarf technology investments. Baby Boomers are retiring, creating a skilled worker gap. Younger generations (Gen Y, Z, and upcoming Alpha) have fundamentally different expectations about physical labor. They won't take jobs that destroy their bodies – they expect technology to compensate for physical strain or they'll work elsewhere.

When you lose workers, the costs multiply:

Absenteeism at €250-800 per day

Recruitment and onboarding expenses for replacements

Lost institutional knowledge and lower productivity during training periods

Increased injury risk from fatigued workers making mistakes.

This isn't PR or employee relations theater; it's fundamental capacity planning. If you can't fill roles or retain workers in physically demanding jobs, your production capacity is limited by headcount, not equipment. Exoskeletons expand capacity by making difficult jobs sustainable.

Data-driven exoskeletons unlock process improvement automation can't see. Kuschan completed his PhD on exoskeleton control systems and highlights a critical capability: exoskeletons gather sensor data that reveals what's actually happening on the factory floor versus what you think is happening.

Most manufacturers have rough time-estimates for processes based on initial planning, but processes change and people deviate from them so after a while you don’t have a good picture of what’s really happening on the floor. Exoskeleton sensors capture movement patterns, load data, fatigue indicators, and posture information – all without requiring someone to stand next to workers with a timer.

The applications:

Create accurate ergonomic assessments using only sensor data

Identify where demanding tasks cluster and need process redesign

Feed data into digital twins for scenario planning

Detect fatigue states to enable personalized break timing or task rotation

As one manufacturer case study showed, "We can switch them without causing any injuries" by rotating workers based on real-time fatigue data showing arm-level versus lower-back fatigue patterns.

This is the productivity wedge: exoskeletons don't just reduce injury, they generate data which drives continuous improvement that automation can't capture because robots don't experience human process variations.

Exoskeletons are superior to Humanoids? Vulprecht goes as far as to say that humanoids may NEVER be competitive: "I don't really see humanoid robots as the tool to be implemented in actual production. I don't see humanoid robots as something replacing human workers... by the time a humanoid robot can actually work a simple job in a factory, the mobile manipulators or the stationary manipulators or the exoskeleton technology will have also progressed much further so I don't think a fully Universal humanoid robot will ever be competitive as an automation solution."

The niche where humanoids make sense today? "Black warehouse or black factory where no humans are working" and you're shipping uniform products (like books – all rectangular, weight known from ERP, etc.) and don't want to invest in fixed automation for a 10-20 year timeframe. That's it. For everything else requiring flexibility with humans present, exoskeletons win.

What to do about this:

→ Run 90-day exoskeleton pilots in your three highest-risk roles. Identify the three job functions with (a) highest injury rates, (b) highest turnover, or (c) most difficult-to-fill positions. Deploy exoskeletons (German Bionics, Sarcos, or equivalent active systems) to 5-10 workers per role for 90 days. Track: engagement scores via surveys, safety incident rates, absenteeism days, quality metrics, and most importantly—voluntary adoption rate after the pilot. If workers choose to keep using the systems when given the option to stop, you have proof of value.

→ Involve frontline workers and labor representatives from day one. Multiple vendors report failed deployments where management bought exoskeletons without worker input, leading to resistance and shelf-sitting equipment. Make this a collaborative process where workers define success criteria and test multiple systems before committing to scale.

2. QAD’s agentic AI plus composable ERP beats the traditional 12-24 month ERP disruption model

The Transformation Ground Control podcast, Episode: The Big Gemma Pullback, The Future of Manufacturing Tech, Big Tech Monopolies with Sanjay Brahmawar, CEO of QAD Software (Nov. 12, 2025)

Sanjay Brahmawar took over as CEO of QAD Software six months ago with a clear mandate: transform manufacturing from systems of record to systems of action. The strategy is already deployed in 1,700+ plants with 650,000 frontline workers using it daily, achieving 26% productivity increases, 81% higher employee engagement, and 35% lower attrition.

TLDR:

Rather than forcing manufacturers to rip out legacy systems, QAD's agentic AI layer pulls data from PLM, MES, and existing ERPs to deliver outcomes, recognizing there's "no ROI" in 12-24 months of business disruption just to modernize tech.

Digital transformation shouldn’t live in the back office or the server room; it should empower frontline employees, turning the shop floor into a continuous learning environment.

The manufacturing landscape is brutal right now, so manufacturers can’t spend 12-24 months scoping ERP upgrades. You need adaptive ERP systems that sense, learn, and respond fast.

Stop thinking “ERP replacement,” start thinking “intelligent overlay.” Most manufacturing leaders face a painful choice: continue limping along with legacy ERP systems that can't adapt quickly, or commit to 12-24 months of business disruption for a new implementation.

QAD's Champion AI creates an agentic layer that sits on top of existing systems – whether it's SAP, Oracle, or homegrown solutions. The AI agents interact with your current PLM, MES, and ERP systems without requiring you to change them.

This matters because manufacturers have "sunk investments" in systems and high switching costs because employees are used to them.

This isn't about buying more tools. It's about better outcomes. The agentic layer handles mundane tasks (a planner who normally navigates five UIs and creates six reports now has everything ready in the morning), solves complex problems (inventory carrying cost optimization showing 15-20% reductions), and accelerates implementations (90-day deployments versus 12-24 months).

Empower the frontline, not just the back office. The biggest blind spot in manufacturing digital transformation is assuming technology should live in the back office or the server room.

QAD's Red Zone platform flips this. It's deployed directly to frontline workers on iPads and Android devices, pulling real-time data from ERP, MES, and PLM systems and delivering it to the person on the shop floor at the exact moment they need it.

The impact is measurable. Across 1,700 plants running six million production runs annually, manufacturers see 26% productivity increases, 81% more employee engagement, and 35% lower attrition.

Why? Because the technology turns the shop floor into a continuous learning environment where problems get addressed immediately instead of waiting weeks for root cause analysis.

Deploy adaptive systems that respond in hours, not months. The manufacturing landscape is brutal right now: tariffs, supply chain disruptions, geopolitical shifts, nearshoring demands.

Manufacturers need systems that can "sense, learn, and respond at pace." QAD's Adaptive ERP does exactly that, with deployment methodologies that target 90 days for new plants and months (not years) for existing operations.

Contrast this with traditional ERP implementations. Most manufacturers spend 12-24 months in scoping, design, and change management before seeing value. By the time the system goes live, market conditions have changed.

QAD's approach recognizes that "adaptive systems or adaptive applications are ones that can sense, learn and respond... it shouldn't take months and years to implement changes. Systems should be able to respond in hours instead of weeks."

What to do about this:

→ Audit your current ERP replacement plans for hidden disruption costs. If you're planning a 12-24 month ERP implementation, calculate the true cost: lost agility during implementation, opportunity cost of frozen processes, business risk from major disruption. Compare this to a composable approach that layers intelligence on existing systems.

→ Pilot an AI agent for your most painful manual task. Identify the single most time-consuming task your planners, schedulers, or production managers do daily (navigating multiple systems, creating reports, optimizing parameters). Deploy an AI agent specifically for that task as a 30-60 day proof of concept.

→ Test frontline worker technology in your highest-turnover roles. Deploy a connected workforce solution in the three production roles with highest attrition or most quality issues. Track engagement, error rates, and retention over 90 days.

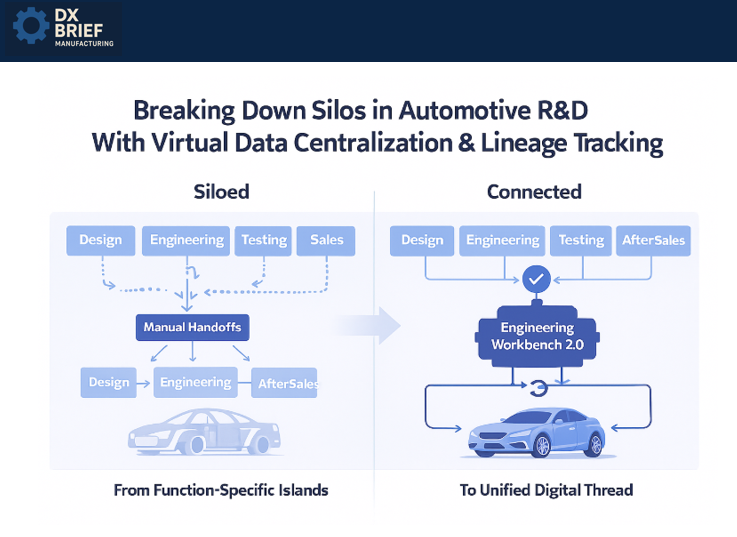

3. How Nissan is breaking down silos in Automotive R&D with virtual data centralization and lineage tracking

MOTOTECH 2025 event: Driving the future of automotive manufacturing, Session: Engineering Workbench 2.0: How Centralized Data Systems Are Reshaping Automotive R&D with Jasmine Gorimar (Nissan) (Nov. 13, 2025)

Automotive R&D teams at companies like Nissan waste enormous amounts of time on manual handoffs between design, engineering, testing, and production. Marketing doesn't talk to sales, sales doesn't talk to after-sales, design doesn't talk to engineering. Engineering Workbench 2.0 is Nissan's answer: a unified, data-driven digital environment that connects every stage of automotive development through a single source of truth.

TLDR:

The future of manufacturing is "AI engineers" where human-AI collaborative design enables hyperpersonalized vehicles that learn from field data and enable continuous engineering post-sale through over-the-air updates and closed-loop product development.

Data can be "virtually centralized" through data catalogs and marketplaces without physically consolidating into one warehouse, giving business users the impression of centralization while keeping specialty databases distributed globally.

Data centralization doesn't mean physical centralization – virtual integration is the real breakthrough. The key is creating a data catalog or data marketplace that gives business owners the impression that data is centralized and accessible from a common location, even though the actual data remains in distributed systems optimized for their specific purposes.

This matters because forcing physical centralization often breaks existing workflows and creates massive migration risks. Virtual centralization through modern data fabric architectures lets you maintain operational continuity while gaining the benefits of unified access.

Track data lineage, not just data is about trust, not storage. Engineering Workbench 2.0 relies on "source of truth" as a core principle, which involves far more than just knowing where data lives. It means tracking how that data was generated, when it was generated, and how it gets utilized through its data lifecycle.

This distinction is critical for manufacturers dealing with global compliance, quality tracking, and continuous improvement loops. When designs happen in one part of the world and testing happens in another to comply with local regulations, understanding data provenance enables closed-loop feedback from market performance back to design teams way ahead in the product journey.

Build for smart automation, but remember: AI is only as good as your data. Most manufacturers rush to implement AI and machine learning without addressing data quality first. "No matter how excellent your algorithm is, how your ML ops features work, if your data is inaccurate or altered or defined for a different purpose, your AI won't deliver value."

Engineering Workbench 2.0 puts data strategy at the foundation, defining who owns the data, how data lineage is tracked, how data quality and accessibility are governed. Only then do automation and AI capabilities layer on top.

This is the opposite of what most manufacturers do: they deploy AI pilot projects hoping for quick wins, then wonder why the technology doesn't scale.

Real-time co-creation across global teams, but only if you solve the handoff problem first. The vision is compelling: design teams and test teams working together simultaneously, supplier test results flowing seamlessly back to prototype designers, unified digital threads connecting the entire value chain. But you can't jump straight there.

Start by answering: Who owns the data at each stage? Was it signed off and verified before handoff? How do supplier and partner integrations actually work? Can their component test results from one supplier integrate with another supplier's data and flow back to your central design team?

These are not technology questions, they're process and governance questions. Engineering Workbench 2.0 works because Nissan addressed simplified handoffs, clear data ownership, and supplier integration protocols before attempting real-time collaboration at scale.

What to do about this:

→ Map your current data landscape before any technology investment. Identify where critical engineering and production data lives (which systems, which geographies), who owns each data set, what the current quality levels are, and where the biggest handoff bottlenecks exist between functions. Don't skip this step to jump straight to AI pilots.

→ Pilot virtual data centralization using a data catalog approach. Rather than attempting to consolidate all manufacturing data into one physical location, implement a data catalog or data marketplace that provides unified discovery and access while keeping data in optimized systems.

Disclaimer

This newsletter is for informational purposes only and summarizes public sources and podcast discussions at a high level. It is not legal, financial, tax, security, or implementation advice, and it does not endorse any product, vendor, or approach. Manufacturing environments, laws, and technologies change quickly; details may be incomplete or out of date. Always validate requirements, security, data protection, labor, and accessibility implications for your organization, and consult qualified advisors before making decisions or changes. All trademarks and brands are the property of their respective owners.