The Automation Gap, the Hidden Factory, and the Cost of Doing Nothing

Every week, we interview practitioners and distill industry podcasts and conferences into what you need to know

In today's issue:

Why the US is running a foot race against Asia's Ferraris!

The “hidden factory” is eating your margins! Hubbell’s solution? The dashboard ecosystem.

Is 80% of your time is wasted in “integration hell”? (here’s how to fix it)

1. Why the US is running a foot race against Asia's Ferraris!

IEX 2025 Charlotte with Torian Richardson (CEO DBR77 US), Celestine Pressley (Gartner AI ambassador, former White House CIO), and Piotr Wiśniewski (Founder & CEO DBR77): The Future of Manufacturing (Dec 16, 2025)

Background: Asia has 73% of its manufacturing integrated with automation, measurement, or robotics. The US sits at 7%. That's not a typo. At IEX 2025 in Charlotte, DBR77's leadership team and Gartner's Celestine Pressley laid out why the American manufacturing sector is sitting in slowly boiling water, and what the data says about the path forward.

TLDR:

The automation gap between the US (7%) and Asia (73%) represents an "industrial tax" that compounds annually. With 700,000 new robots deploying globally by 2026, only a small fraction will land in American factories.

Stop measuring AI success by models deployed. Instead, tie every initiative to operational metrics like OEE, first-pass yield, or scrap reduction. Nearly half of all AI initiatives fail to meet ROI expectations because they're measured with IT metrics, not business metrics.

Before investing in robots, fix your OEE first. If your plant runs at 40% efficiency, robots will spend 60% of their time waiting on human processes, destroying your payback period.

You're in the wrong race, and you might not even know it. Celestine Pressley, former CIO of the White House Trade Office and now at Gartner, opened with a metaphor: "Picture yourself at a starting line. You've trained hard. But then you look left and right and realize one competitor is in a Porsche, the other in a Ferrari. You're on foot." This is the AI race as her manufacturing clients describe it.

But here's the crucial distinction: there are two races happening. The AI vendor race floods the market with new AI-enabled products every 2.5 days. That's not your race. The AI outcome race – delivering measurable results on business outcomes, technology governance, and workforce impact – is what you should be running. Nearly half of technology leaders report their AI initiatives haven't met ROI expectations because they're running the wrong race.

The numbers that should wake you up. Piotr Wiśniewski brought the receipts from DBR77's work with 500+ manufacturers: China deploys in 50 days what the US deploys in a year. Japan sees 40% output increases when integrating automation. And by 2026, 700,000 new robots will be installed globally, with the vast majority going to Asia.

The sobering context: two million manufacturing jobs will go unfilled in the US by 2030, with 67% of the remaining workforce over 45. This isn't about robots replacing workers. It's about robots filling gaps that humans literally cannot fill.

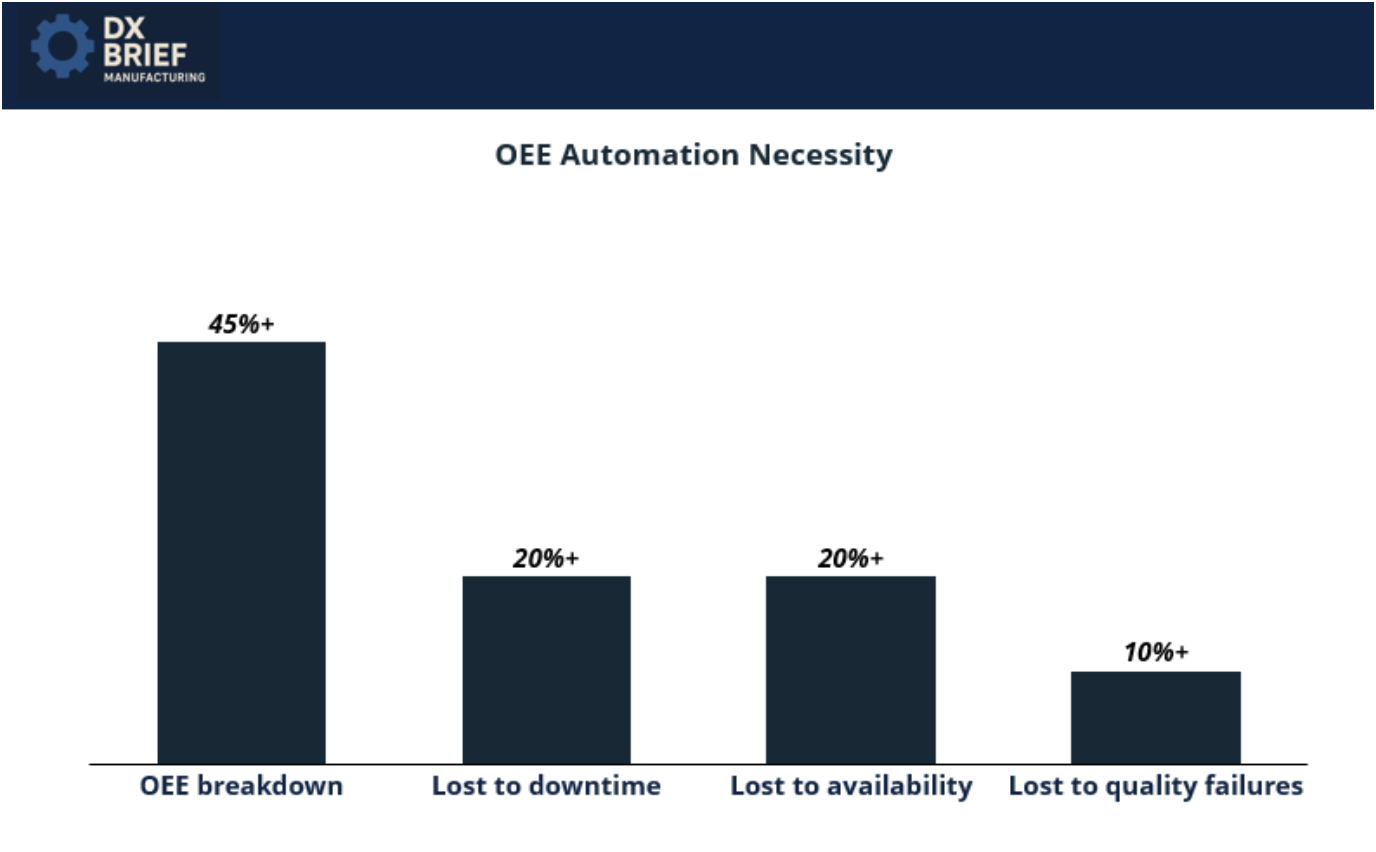

OEE is the gatekeeper nobody wants to talk about. Before you deploy a single robot, Wiśniewski's message was blunt: measure your Overall Equipment Effectiveness. If your plant runs at 40% OEE (common in non-automotive manufacturing), your robot will sit idle 60% of the time waiting on human processes. "It's no sense to put robots there," he said. Target 70-75% OEE before major automation investments, or you're automating waste.

He described a typical 45% OEE breakdown: 20% lost to downtime, 20% lost to availability issues, 10%+ lost to quality failures. Fix maintenance and material flow alone – just those two variables – and he guarantees 20% efficiency gains.

What to do about this:

→ Audit your real OEE today, not your reported OEE. Most plants overstate efficiency by excluding "acceptable" losses.

→ Apply the build-buy-blend framework before any AI purchase. Buy off-the-shelf for common problems (supply chain visibility). Build only for core functions competitors can't replicate. Blend – using vendor software customized with your proprietary data – is usually the sweet spot.

→ Require digital twin simulation for any capital investment over $500K. Make it policy. No steel gets cut until the virtual version proves the ROI.

→ Start workforce augmentation conversations now. The data shows highest productivity gains come from human-AI collaboration, not replacement. Frame automation as "intelligence amplification" and begin skills assessment for your current team.

2. The “hidden factory” is eating your margins! Hubbell’s solution? The dashboard ecosystem.

CAI Software / SAP Insider Webinar with Jeff Elam, Global Operations Systems Manager @ Hubbell (32 years), and Craig Powers, SAP Insider Analyst (Dec 18, 2025)

Background: Jeff Elam has spent 32 years at Hubbell, the last several years deploying MES and data systems across 80+ manufacturing sites globally. He's seen what happens when operator data doesn't speak to executive data: dangerous blind spots that cost money and slow decisions. Here's the dashboard ecosystem framework Hubbell uses to ensure data flows from the shop floor to the CEO without losing fidelity or context.

TLDR:

79% of factory workers still rely on paper-based documentation: management often hesitates to digitize because they fear technology will create more work, but frontline workers are ready to embrace digital tools.

The "dashboard ecosystem" concept ensures operator data rolls up through supervisors, engineers, and plant management to the executive suite. Each role gets their specific view, but everyone works from the same data foundation.

SAP Insider research shows companies progressing through data maturity stages see significant KPI improvements in productivity, forecast accuracy, and decision speed. The investment delivers measurable returns.

The hidden factory is eating your margins… and paper can't see it. The "hidden factory" describes all the unplanned, unnecessary, or non-value-added activities happening within your operations. Scrap. Rework. Untracked downtime. Quality escapes. These losses hide in plain sight because paper-based processes can't surface them in real time.

Research from CAI Software reveals that 79% of factory workers still rely on paper-based documentation. Management resists digitization, fearing it will burden employees. But the reality has shifted: frontline workers are ready for digital tools. The hesitation sits with leadership, not the floor.

Build a dashboard ecosystem, not isolated dashboards. Many manufacturers deploy "fancy dashboards" that exist in isolation. A supervisor sees one view. Finance sees another. Neither connects to what operators experience in real time. Hubbell's approach treats data architecture as an ecosystem where every dashboard inherits from the same foundation.

The structure works like this:

Operators see machine status, production count, cycle time, and quality checks – real-time, actionable data that drives minute-by-minute decisions.

Supervisors see aggregated line OEE, throughput, and downtime causes.

Engineers see trending data for root cause analysis and process optimization.

Plant managers see aggregate performance across departments.

And executives see cross-site comparisons that inform capital allocation and strategic priorities.

The critical insight: "If the CEO can't see the financial impact of a machine that went down on the shop floor, you don't have a foundation – you have silos." Every piece of operational data must feed a strategic outcome.

Data maturity is a journey with measurable returns. Craig Powers from SAP Insider shares research tracking companies across three maturity levels:

Stage 1 “data beginners” is about visibility: understanding current status and capturing low-hanging fruit.

Stage 2 “data adopters” turns data into knowledge: understanding why adverse events happen.

Stage 3 “data leaders” moves into prediction: anticipating problems before they occur.

Most manufacturers sit at stage 1 today. As companies progress, they see compounding improvements in productivity, forecast accuracy, decision speed, and data quality. Getting to stage 2 or 3 represents genuine competitive advantage.

What to do about this:

→ Map your current dashboard ecosystem. Document every dashboard in use across your organization. Ask: Does the operator's data flow to the supervisor? Does the supervisor's data inform the engineer? Does the engineer's analysis reach the CFO? Gaps in this chain are gaps in visibility.

→ Start with four operator metrics. Hubbell's foundation begins with machine status (running/idle/faulted), production count, cycle time, and instant quality checks. These four data points drive immediate decisions and cascade insights upward.

→ Let supervisors coach with data, not observations. The most transformational benefit Hubbell reports: supervisors can now approach operators with objective data points rather than subjective observations. This shifts conversations from fault-finding to fact-finding and turns supervision into mentorship.

3. Is 80% of your time is wasted in “integration hell”? (here’s how to fix it)

QKS Group SPARK Insights Live: Industrial AI & Edge 2026 – From Connected Assets to Intelligent Operations (Dec 10, 2025)

Background: The QKS Group analyst team just completed their 2025 review of industrial AI implementations, drawing from SPARK Matrix evaluations, enterprise engagements, and vendor briefings across the manufacturing sector. Their finding: while connected technology scaled dramatically in 2025, most organizations spent 80% of their time building custom connectors and only 20% realizing value. The gap between "connected" and "integrated" became the defining failure mode of the year.

TLDR:

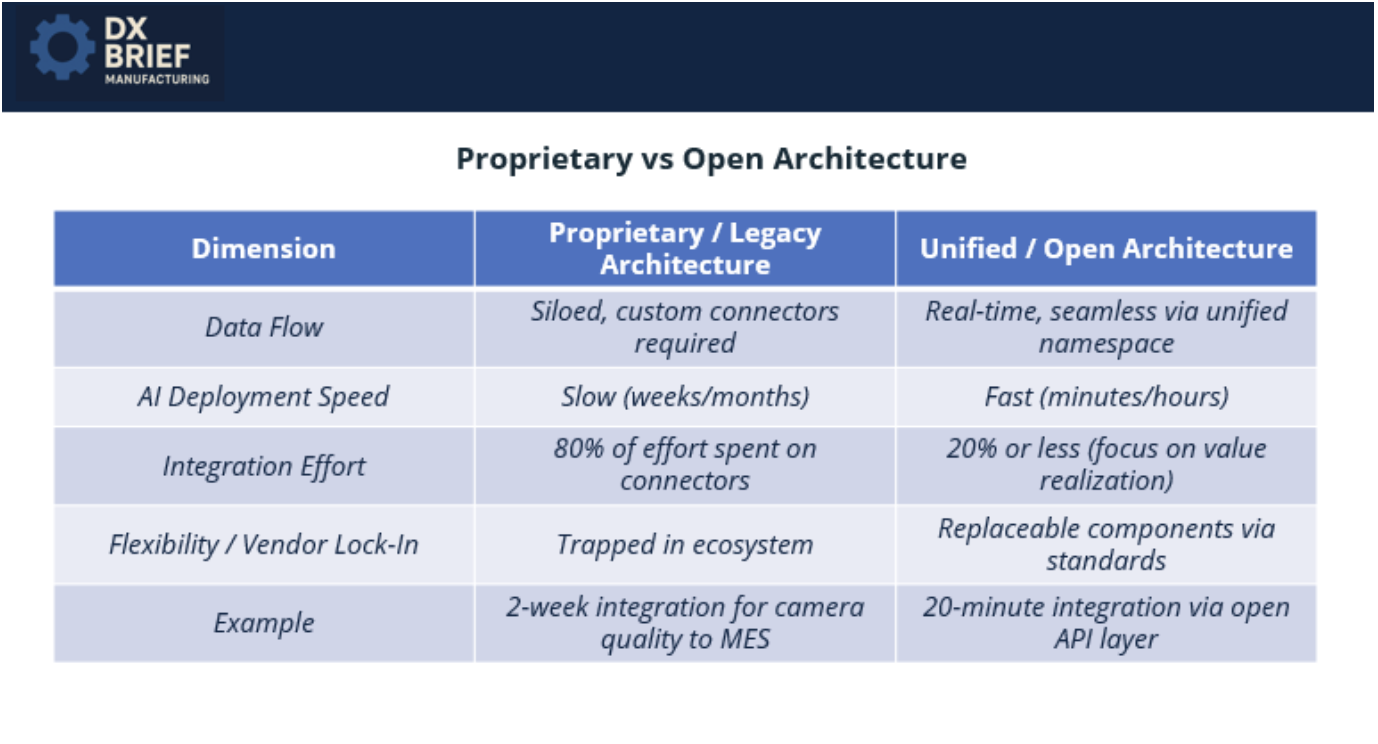

The bottleneck isn't AI technology, it's architecture. Companies bolt AI onto legacy systems not designed to share data, then spend 80% of effort on "integration hell" with custom connectors.

"Unified namespace" or single data layer is no longer optional. It's the prerequisite for scaling any AI initiative beyond pilot stage.

Open standards and interoperability are becoming non-negotiable. Proprietary platforms that worked in 2024 will slow you down in 2026.

Architecture matters more than any individual use case. The QKS team identified the core failure pattern: "Many companies tried to bolt on AI to legacy systems that were not inherently designed to share data. So what they do is that they put AI first but then they spend 80% of their time building custom connectors and what we call internally integration hell."

The math is brutal. Following the 80/20 rule in reverse: 80% of effort goes to integration, only 20% to value realization.

One manufacturer shared a specific incident: their furnace was running below target temperature, but maintenance never saw the alert because quality, SCADA, and MES were three separate systems that didn't communicate. The lack of unified data architecture became the barrier to scaling AI.

Build the unified namespace before adding more AI. The strategic pivot the QKS team is seeing: "We're moving towards a unified data fabric instead of the spaghetti mess of wires. You can imagine a circular integrated ecosystem where data flows freely between IT and OT layers, acting as a single source of truth enabling instantaneous visibility."

This isn't about choosing the right AI model. It's about creating the foundation on which any AI model can operate.

Their recommendation: "You cannot scale intelligent operations on a fragmented foundation. Companies should opt for what we call the unified namespace or a single data layer so that when you do deploy AI, the data is already clean, contextualized, and ready to use."

Proprietary platforms are now a liability. The organizations that made the most progress in 2025 "adopted a vendor-agnostic mindset. They wanted the freedom to choose the best component for each job – the best connectivity platform, the best platform for data management – without being trapped in a single ecosystem."

The QKS team saw a concrete example: "One manufacturer was running Siemens PLCs, an Advantech gateway, and an AWS edge runtime, and everything worked smoothly because the architecture was standards-based."

Compare this to organizations where "pulling camera quality data into MES used to take two weeks of custom integration. But once they moved into an open API layer, it took them 20 minutes."

The implication for vendor selection: "If a component is not really giving you value, you can replace it without redesigning your entire architecture. That actually keeps the long-term cost and risk under control."

What to do about this:

→ Calculate your current integration-to-value ratio. Track how much time your teams spend on data integration, connector building, and system reconciliation versus time spent on analysis and improvement. If it's anywhere near 80/20, prioritize architecture over new AI initiatives.

→ Assess your data architecture against the unified namespace model. Can you get a single, contextualized view of operations in real-time? If your quality, maintenance, and production data live in separate systems that don't automatically share, that's your bottleneck.

→ Audit your vendor contracts for lock-in terms. Check whether your current platforms allow easy data export, third-party AI model integration, and standards-based connectivity. If not, factor this into your 2026 procurement strategy.

Disclaimer

This newsletter is for informational purposes only and summarizes public sources and podcast discussions at a high level. It is not legal, financial, tax, security, or implementation advice, and it does not endorse any product, vendor, or approach. Manufacturing environments, laws, and technologies change quickly; details may be incomplete or out of date. Always validate requirements, security, data protection, labor, and accessibility implications for your organization, and consult qualified advisors before making decisions or changes. All trademarks and brands are the property of their respective owners.